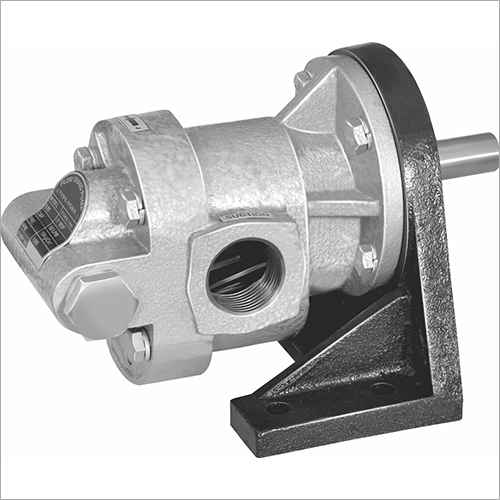

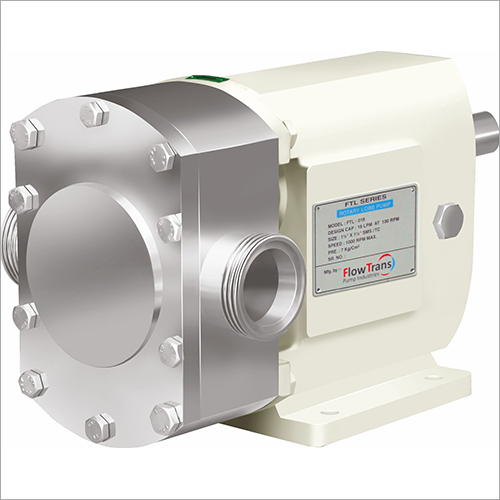

Tri Lobe Pumps

Tri Lobe Pumps Specification

- Voltage

- 220V / 380V / 440V

- Caliber

- 25 mm to 100 mm

- Discharge Pressure

- Up to 12 Bar

- Frequency

- 50Hz / 60Hz

- Max Suction

- Up to 8 meter

- Flow Rate

- 0.2 to 60 m/hr

- Head Size

- 10-120 Meter

- Features

- Reversible Flow, Hygienic Design, Easy Dismantling & Cleaning, CIP/SIP compatible

- Control System

- Manual or Automated

- Speed

- 100-1000 RPM

- Theory

- Rotary Lobe Pump

- Mounting Type

- Base Plate Mounted

- Noise Level

- Low Noise Operation

- Inlet/Outlet

- Threaded or Flanged

- Working Temperature

- -10C to 120C

- Material

- Stainless Steel / Cast Iron

- Structure

- Horizontal

- Power

- 0.5 HP to 20 HP

- Standard

- ISO / GMP / 3A (on demand)

- Fuel Type

- Electric

- Pressure

- Up to 12 bar

- Usage

- Industrial / Food & Beverage / Dairy / Pharmaceutical

- Application

- Transfer of Viscous Liquids, Syrup, Juice, Cream, Paste, Chocolate, etc.

- Suction Type

- Positive Displacement

- Seals Type

- Mechanical Seal / Lip Seal

- Priming

- Self-Priming

- Pump Type

- Tri Lobe

- Capacity

- 0.2 60 m/hr

- Pump Casing

- Investment Cast / Fabricated

- Ambient Temperature Limit

- -20C to 50C

- Maximum Viscosity

- Up to 1,000,000 cP

- Cleaning Compatibility

- CIP (Clean-in-Place) / SIP (Sterilize-in-Place)

- Surface Finish

- Electropolished (Internal Ra 0.8m)

- Seal Cooling

- Provision available for flushed seals

- Rotor Type

- Bi-wing / Tri-lobe / Multi-lobe

- Lobe Material

- Stainless Steel (SS316/SS304)/Non-Metallic Options

- Direction of Rotation

- Bi-directional

- Drive Option

- Electric Motor / Gearbox / VFD

- Installation

- Horizontal / Vertical (on request)

- Protection Class

- IP55 / IP65 (Motor)

- Port Connections

- DIN / SMS / IDF / RJT / Clamp / Flanged

Tri Lobe Pumps Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- MUNDRA

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 1000 Pieces Per Year

- Delivery Time

- 1 Week

- Main Domestic Market

- All India

About Tri Lobe Pumps

Leveraging on our state-of-the-art infrastructural unit, we have been a prominent manufacturer of an extensive array of Tri-Lobe Pumps to our highly reputed clients. They are used at varied places to suit the requirements of customers. Fine quality raw material is obtained from our dependable vendors and processed using hi tech machinery at our unit for making these Tri-Lobe Pumps. They are hence known for their optimum quality, durability, finishing, corrosion resistance and compact design. This has gained us high rising demands for these pumps in the market.

The FTL pump is a positive displacement rotary lobe pump of a sanitary design suitable for use in the dairies, food-processing, beverage, cosmetics, pharmaceutical and fine chemicals industries. This rotary lobe pump is perfect for managing all kinds of fluid, of either low or high viscosity, as well as for filtering and bottling applications. Products containing fragile solids such as junket can be pumped without damage thanks to the specially designed lobes.

Operating principle

The FTL rotary lobe pumps basically consist of two lobe rotors which rotate synchronously inside a casing without touching each other. As the rotors rotate, the spaces between the lobes and the casing are successively filled with the product, which is transported to the discharge nozzle with a fixed amount of displacement. The pumped fluid forms a continuous stream thanks to the tolerances between the lobes and the pump casing, thus ensuring an efficient pumping.

Overview

Size from 1" to 4", Capacity 1500 LPM max, Working Pressure 10KG/CM2,

Hygienic and Robust Construction

Engineered in stainless steel or non-metallic variants, with electropolished surfaces, Tri Lobe Pumps meet stringent sanitation standards for critical applications. Their modular, investment cast or fabricated casing supports easy inspection and maintenance, ensuring reliability in demanding environments such as pharmaceuticals and food processing. The design incorporates handcrafted rotors, optimal for high viscosity fluids and ranging from bi-wing to multi-lobe configurations.

Flexible Operation and Installation

These pumps operate bi-directionally and accept a wide range of port connections, including DIN, SMS, IDF, RJT, clamp, or flanged options. Installation is possible in both horizontal and vertical orientations based on site requirements. Various drive configurations (electric motor, gearbox, VFD) and voltages (220V, 380V, 440V) ensure adaptability to diverse industrial setups, while manual or automated controls further enhance operational convenience.

Comprehensive Performance Range

Tri Lobe Pumps are compatible with highly viscous fluids (up to 1,000,000 cP) and facilitate flow rates from 0.2 to 60 m/hr, with discharge pressures up to 12 bar and maximum suction up to 8 meters. The pumps deliver precise, low-noise operation across a working temperature range of -10C to 120C. Their self-priming and positive displacement functionality makes them especially valuable for applications demanding consistent, clog-free fluid transfer.

FAQs of Tri Lobe Pumps:

Q: How do Tri Lobe Pumps ensure hygienic processing in industries like food and pharmaceuticals?

A: Tri Lobe Pumps feature electropolished stainless steel construction (Ra 0.8m) and are designed for easy dismantling, cleaning, and compatibility with both CIP (Clean-in-Place) and SIP (Sterilize-in-Place) processes. This ensures hygienic fluid transfer and minimal risk of contamination in sanitary environments.Q: What types of liquids can Tri Lobe Pumps handle, and what is the maximum viscosity supported?

A: Tri Lobe Pumps are engineered to handle a wide range of viscous products, including syrups, juices, creams, pastes, and even chocolate. They support the transfer of fluids with viscosities up to 1,000,000 cP, making them suitable for a broad spectrum of industrial, food, dairy, and pharmaceutical applications.Q: When should a Tri Lobe Pump be used instead of other pump types?

A: Tri Lobe Pumps are ideal when gentle, low-shear transfer of high-viscosity fluids is required, especially in processes demanding hygiene and reliability. They are preferred when self-priming, reversible flow, and low-noise operation are important, such as in the food, beverage, pharmaceutical, and dairy sectors.Q: Where can Tri Lobe Pumps be installed, and what mounting options are available?

A: Tri Lobe Pumps can be installed in either horizontal or vertical orientations depending on application requirements. They are base plate mounted and can be tailored for various installation settings, ensuring flexibility for industrial sites and manufacturing plants.Q: What is the process for cleaning and maintaining the Tri Lobe Pump?

A: The hygienic design of the pump allows for tool-free dismantling, making inspection and cleaning straightforward. The pumps are CIP and SIP compatible, permitting automated in-line cleaning or sterilizing without the need for disassembly, which saves downtime and supports compliance with hygiene standards.Q: How does seal cooling provision benefit the operation of the pump?

A: The provision for flushed seal cooling helps maintain seal integrity when handling hot or volatile fluids, preventing process leaks and extending the service life of the pump. This feature is especially vital in industries that use aggressive cleaning regimes or process high-temperature fluids.Q: What are the main benefits of using a Tri Lobe Pump in industrial applications?

A: Users benefit from reliable and efficient fluid handling, low maintenance, compatibility with a wide range of fluids, high pressure capability (up to 12 bar), and flexibility in drive and installation. Their robust, hygienic, and self-priming designs ensure minimal downtime and consistent performance in critical operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

|

FLOW TRANS PUMP INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |