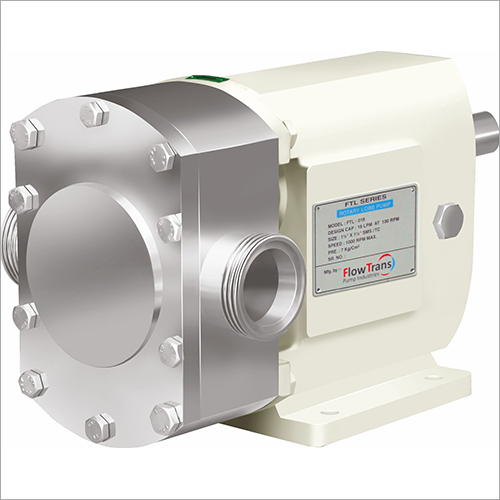

Syrup Pump

Syrup Pump Specification

- Discharge Pressure

- 2.5 Bar

- Head Size

- 20 Metres

- Frequency

- 50 Hz

- Noise Level

- < 45 dB

- Features

- Compact design, hygienic, easy to clean

- Inlet/Outlet

- 1/2 inch

- Max Suction

- 5 Metres

- Working Temperature

- -10C to 80C

- Caliber

- 14mm

- Flow Rate

- 10-20 L/min

- Voltage

- 220V

- Control System

- Manual

- Speed

- 1440 RPM

- Theory

- Rotary Pump

- Mounting Type

- Base Mounted

- Material

- SS304 Stainless Steel

- Structure

- Single-stage

- Power

- 0.5 HP

- Standard

- ISI/ISO certified

- Fuel Type

- Electric

- Pressure

- 2.5 Bar

- Usage

- Syrup transfer

- Application

- Food, Pharma & Beverage Industries

- Suction Type

- Positive Suction

- Seals Type

- Mechanical Seal

- Priming

- Self-priming

- Pump Type

- Syrup Pump

- Capacity

- 20 L/min

- Surface Finish

- Mirror polished

- Cleaning Type

- CIP compatible

- Dimension (L x W x H)

- 380mm x 165mm x 250mm

- Impeller Type

- Closed Impeller

- Installation

- Horizontal

- Weight

- 12 kg

- Protection Class

- IP54

- Connection Type

- Threaded/Sanitary Clamp

- Viscosity Range

- Up to 10000 cP

- Portability

- Portable with carry handles

- Service Life

- Up to 20,000 hours

Syrup Pump Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 1000 Pieces Per Year

- Delivery Time

- 1 Week

- Main Domestic Market

- All India

About Syrup Pump

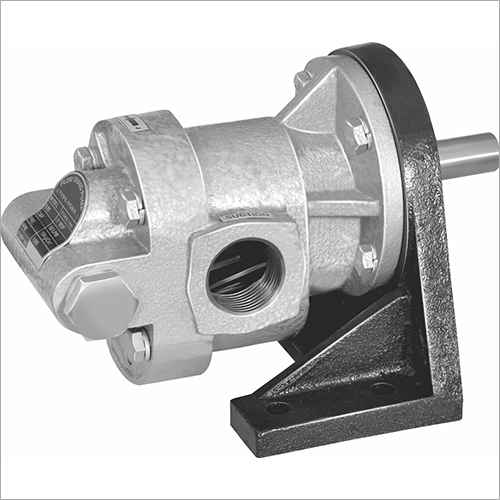

Stainless Steel Gear Pump is a compact & efficient SS pump that finds application for handling food products like ghee, butter fruit pulp, vegetable souse, kanji etc. It is also used in pharmaceutical application for handling sugar solution, glycerine, glycol etc.

- Stainless Steel contact parts

- Leakage free sealing

- Compact and economical

Robust & Portable Design

This syrup pump features a lightweight yet sturdy structure, weighing just 12 kg and equipped with convenient carry handles. Its compact dimensions and base-mounted setup make it ideal for portable applications where space is at a premium, allowing easy relocation within your facility.

Superior Performance and Hygiene

Engineered for the rigorous demands of food, pharma, and beverage processing, the pump boasts a closed impeller, positive suction, and a mirror-polished stainless steel surface. It ensures exceptional sanitary standards and is fully compatible with Clean-In-Place (CIP) procedures, promoting effortless maintenance.

Versatile and Reliable Operation

With its ability to transfer a wide range of syrup viscosities and a robust self-priming system, this pump provides smooth, consistent operation. Designed for both threaded and sanitary clamp connections, it adapts seamlessly to different piping setups while delivering reliable service at up to 20,000 operating hours.

FAQs of Syrup Pump:

Q: How do I properly install the syrup pump for optimal performance?

A: Install the syrup pump in a horizontal position on a stable, base-mounted surface. Connect using either the threaded or sanitary clamp fittings, and ensure all piping is secure. The pumps compact design and carry handles make relocation and installation quick and straightforward.Q: What types of syrups and viscosity levels can the pump handle?

A: This pump is suitable for transferring syrups with viscosity levels up to 10,000 centipoise (cP), making it versatile for a range of products in the food, pharma, and beverage industries.Q: When is it necessary to clean or maintain the syrup pump?

A: Routine cleaning should follow each production batch, especially with sticky or sugary syrups. Its CIP-compatible design allows for efficient, thorough cleaning without disassembly. Maintenance, such as checking seals, should be performed periodically or if any reduction in performance is noticed.Q: Where can this syrup pump be used effectively?

A: This pump is ideal for food processing plants, pharmaceutical production facilities, and beverage manufacturing sites requiring sanitary, reliable syrup transfer. Its portability also makes it suitable for multi-station use within a single plant.Q: What is the process for priming the pump before operation?

A: As a self-priming pump, the system automatically removes air from the suction line. Simply ensure the inlet and outlet are connected and the pump is filled with product before starting operation.Q: How does the pump benefit food and pharmaceutical operations?

A: Its hygienic SS304 stainless steel construction, mirror-polished finish, and easy cleaning capabilities support strict industry sanitation standards. The robust service life and efficient operation enhance productivity and reduce downtime.Q: What are the key advantages of this syrup pump over traditional models?

A: Key benefits include its lightweight, portable design, low noise level (<45 dB), self-priming capability, long service life up to 20,000 hours, and compatibility with clean-in-place cleaning. It adapts to various installation requirements and delivers consistent performance under a wide range of conditions.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

|

FLOW TRANS PUMP INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |